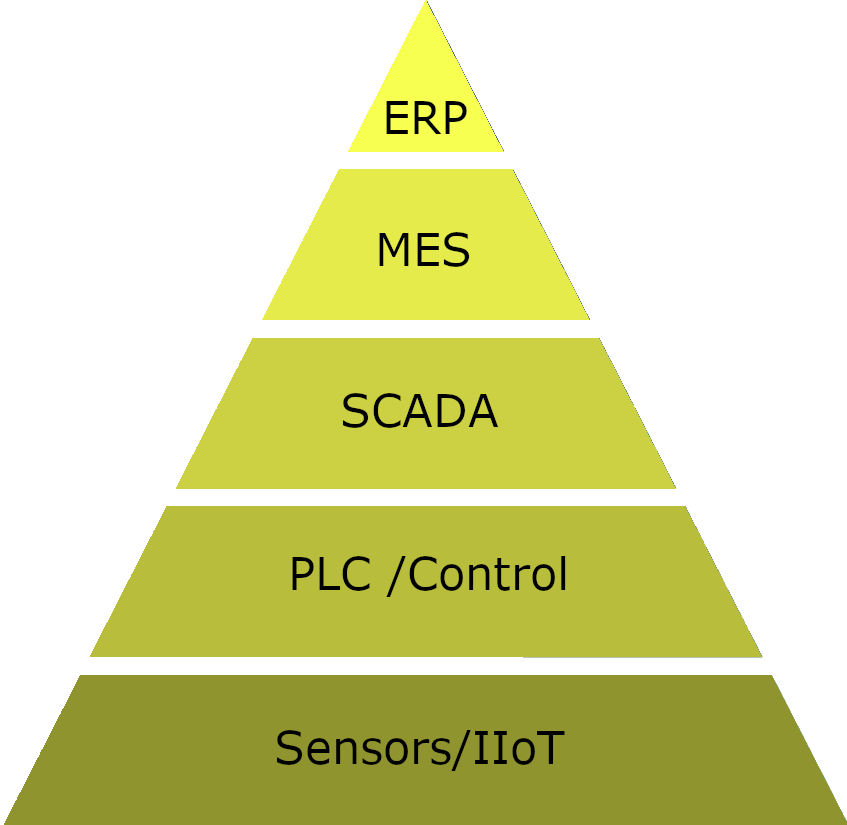

Manufacturing Execution Systems

MES projects are one of the largest, most intricate projects in the industrial sector. Without proper planning and execution, they can be long term expensive project that result in irrelevant or garbage data. Paradigm has the experience to help form useful targets for decision makers, solutions for all levels, and the knowledge of how to setup the infrastructure to set up your project for success.

Level 3: MES

Modern MES can be the driving force for decision-makers for single sites, to entire companies. These systems include systems: OEE, Track and Trace, Downtime Tracking, Batch recipes, Predictive Maintenance, Quality tracking, and a myriad of custom uses. Paradigm can help develop these solutions directly for your needs, rather than using an ineffective pre-canned solution.

Level 2: SCADA

With modern SCADA systems, MES can be used to display data from the MES for production’s needs, creating real-time actionable data. Paradigm excels at displaying useful data and eliminating clutter, while also developing the SCADA infrastructure to make it work.

Level 1: Plc and controls

Using existing controls in place used for the day-to-day production of your factory is the best way to effectively feed reliable data into your MES. Paradigm leverages experience in controls to ensure your upper level data gets this effective information.

Level 0: Sensors and IIOT

Paradigm can help distinguish the most effective way to leverage already existing sensors, and how to add non-control level IIoT sensors for any gaps. The basis of every useful MES is the bedrock of useful, accurate data.